Metalco “AMEGO” Fence System

Metalco Fence Systems

Bring your Design right to the Fence

AMEGO Fence System: The affordable alternative to chain link. Secure and hard to climb. Beautiful and Unobtrusive. With an Amego Fencing System, you get an innovative design that’s compatible with many landscaping approaches.

Environmentally Responsible

Twenty Year Warranty

American Made

25 Years of Experience

- Key Benefits

- CAD Drawings

- Specifications

- Finish & Colors

- Brochures

Key Benefits

- RIGIDITY

- MODULAR SYSTEM

- LONGEVITY

- EASE OF INSTALLATION

- PANELS

- POSTS

- GATES

- COATING

- COLORS

- WARRANTY

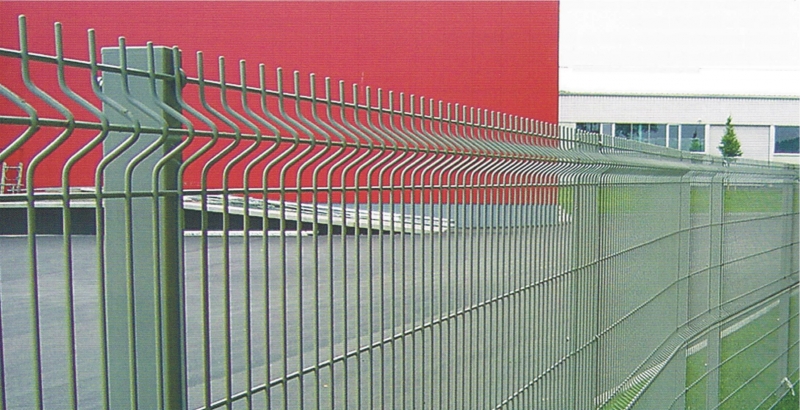

RIGIDITY

Forged welded wire mesh security panels with horizontal reinforcement ribs provide for high strength and rigidity.

MODULAR SYSTEM

The fence system is provided as a complete modular system consisting of panels in various heights, high strength steel posts and attachment hardware. A selection of swing, slide and cantilever gates are available.

LONGEVITY

METALCO’s advanced polyester powder coating system assures lasting colors. The combined protection of galvanization and powder coating ensures best protection against rust and corrosion.

EASE OF INSTALLATION

The AMEGO system components are developed with ease of installation in mind. The system can be installed quickly and efficiently.

PANELS

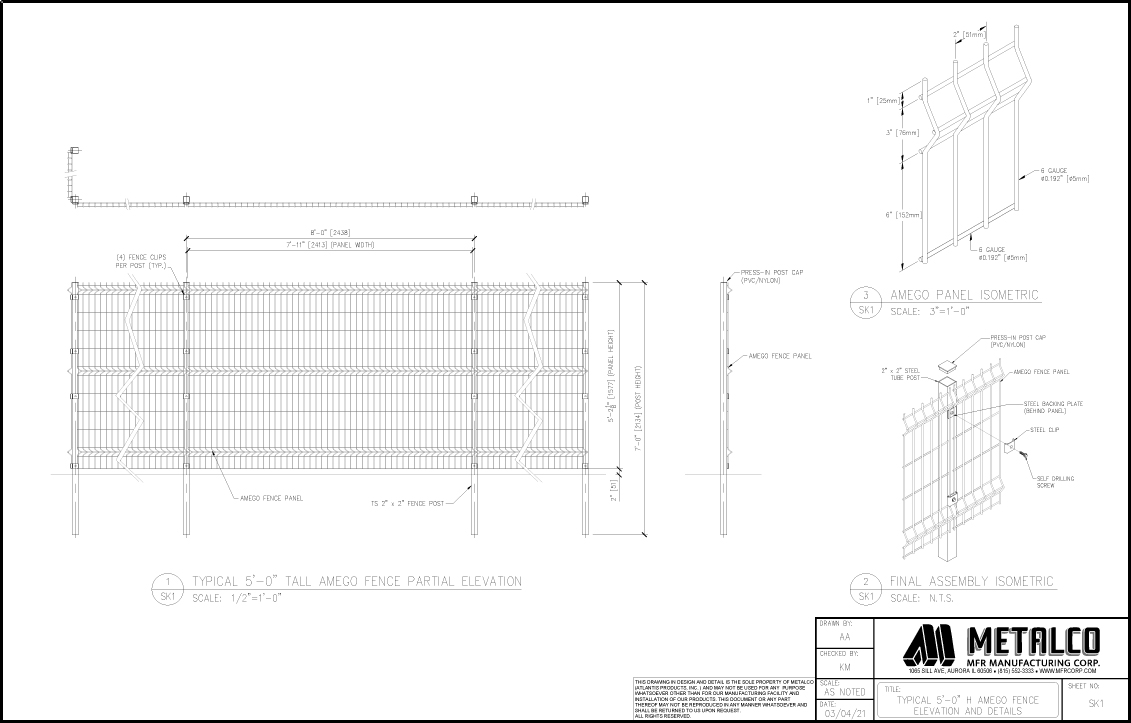

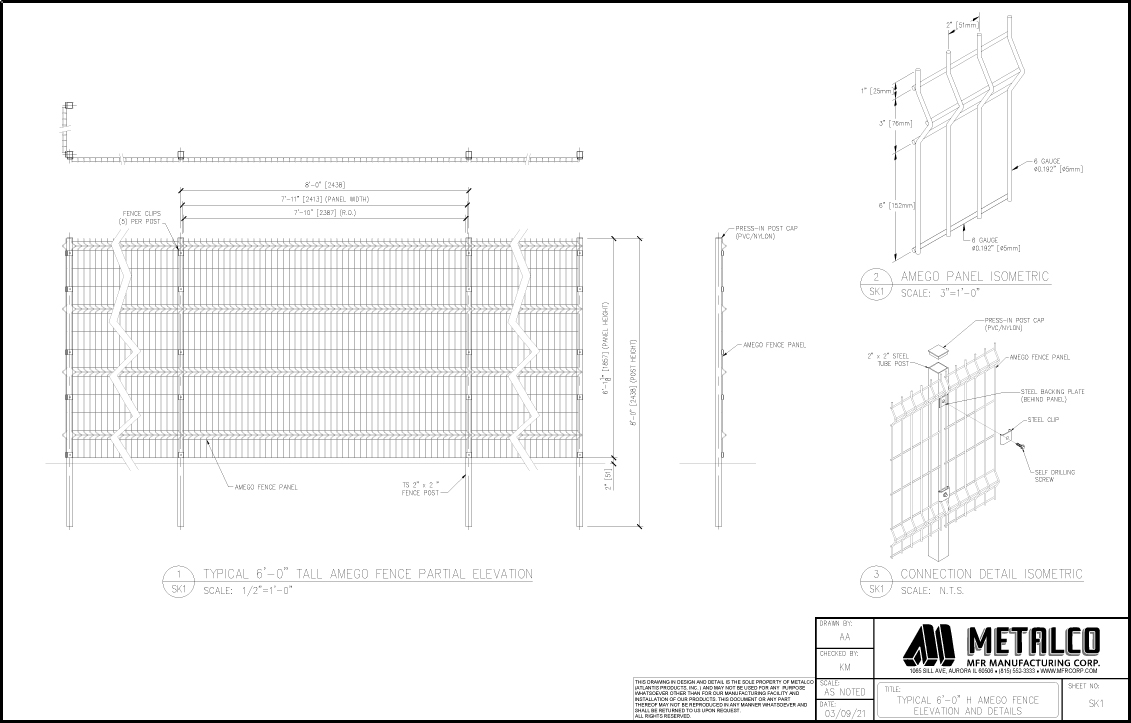

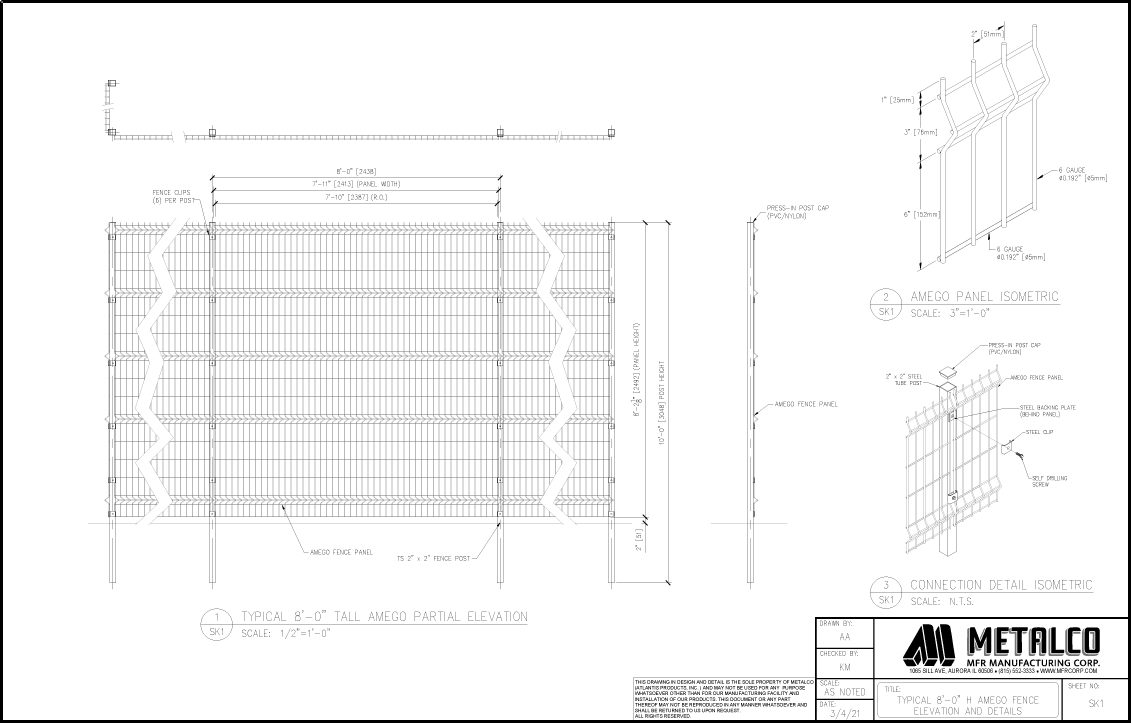

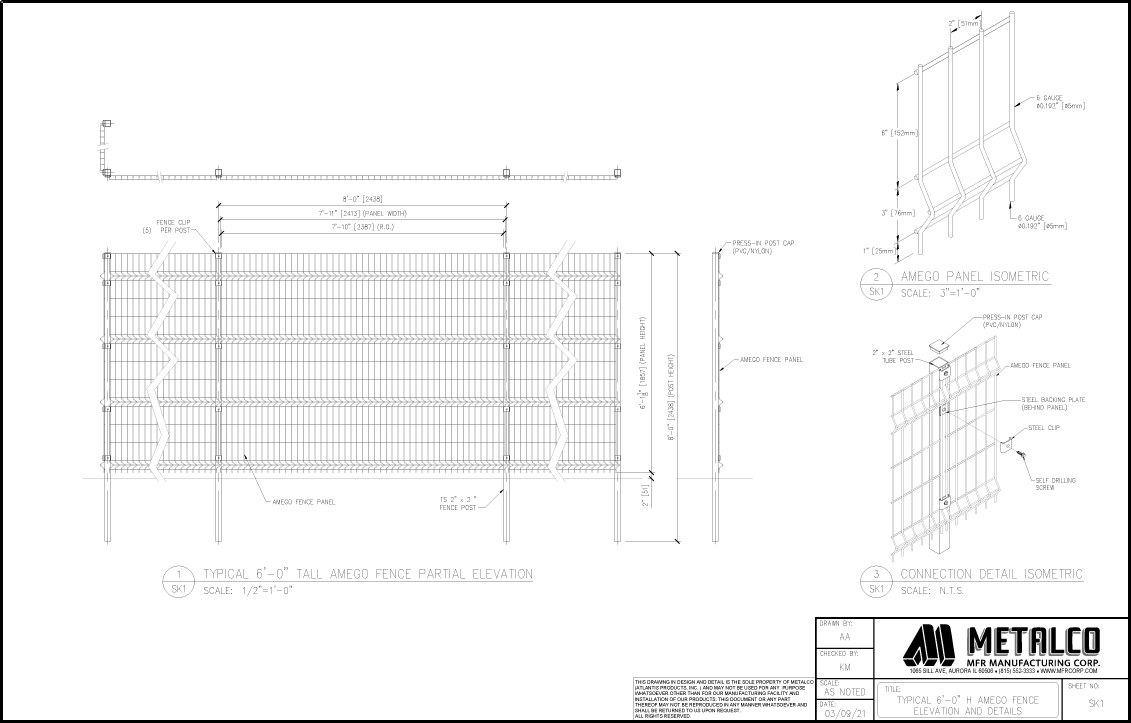

The panels have a width of 7′-11″ (2413mm) and are available in heights ranging from 4ft to 8ft (1200 to 2400mm). The panels have 1″ pickets extending on one side and can be installed either with the pickets at top or at bottom. The mesh size is 2″x 6″ (51x152mm). The forged welded high quality wire assures strength and rigidity. The omega fence shape provides both visual attractiveness and rigidity.

POSTS

The panels are attached to tubular high strength steel posts 2″x2″. The panels can be attached to the face of the posts or in between posts by used of the included high strength attachment brackets.

GATES

The AMEGO Fence System includes a wide selection of swing, slide and cantilever gates.

COATING

The welded mesh panels are produced from galvanized steel wire and coated with an architectural grade polyester powder coating system. Our coating system offers the highest durability available today resulting in lasting colors for many years. In addition to the best protection against rust and corrosion it is also environmentally friendlier (no solvents) than other technologies.

COLORS

The AMEGO fence system is available in a variety of colors. The standard stock color is black. Custom colors are available.

WARRANTY

The AMEGO Fence System is produced by utilizing state of the art manufacturing technology and is backed by our 20-year Manufacturer’s Warranty.

Specifications

“AMEGO” Fence System Specifications

MFR Manufacturing offers technical assistance to architects, engineers, contractors, owners and facility managers regarding the design and installation of our products. We have provided many custom solutions for unusual situations. Let our experienced engineers assist you to determine the optimum design for your project.

PART 1 – GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions.

1.2 SUMMARY

A. This Section includes the following:

1. Fencing System complete with all hardware, posts, rails, gates, and accessories necessary for a complete and aesthetically balanced installation.

2. Swing gates and related hardware.

3. Sliding gates and related hardware.

4. Concrete foundation for posts.

B. Related Sections

1. 03 30 00 Cast in Place Concrete

2. 31 00 00 Earthwork

1.3 REFERENCES

A. American Society for Testing and Materials:

1. ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

2. ASTM A123 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

3. ASTM B 750-99 Galfan Ingot Preparation for Hot Dip Coating of Carbon Steel Wire

3. ASTM A185 Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete

4. ASTM A500 Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

5. ASTM A501 Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing

6. ASTM A856/A 856/M-98 Standard Specification for Zinc- Aluminum (Galfan) Coated Carbon Steel Wire

7. ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus

8. ASTM B633 Standard Specification for Electrodeposited Coatings of Zinc on Iron and Steel

9. ASTM C33 Standard Specification for Concrete Aggregates

10. ASTM C150 Standard Specification for Portland Cement

11. ASTM C207 Standard Specification for Hydrated Lime for Masonry Purposes

12. ASTM D1654 Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

13. ASTM D2248 Standard Practice for Detergent Resistance of Organic Finishes

14. ASTM D2794 Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation

15. ASTM D3359 Standard Test Methods for Measuring Adhesion by Tape Test

16. ASTM D3363 Standard Test Method for Film Hardness by Pencil Test

17. ASTM D4141 Standard Practice for Conducting Black Box and Solar Concentrating Exposures of Coatings

18. ASTM F2408 Standard Specification for Ornamental Fences Employing Galvanized Steel Tubular Pickets

B. American Concrete Institute:

1. ACI 301 Specifications for Structural Concrete

1.4 SYSTEM DESCRIPTION

A. The Manufacturer shall supply a Fencing System complete with all hardware, posts, rails, unions, gates and

accessories necessary for a complete and aesthetically balanced installation.

B. Design Requirements: Fencing system, foundation and installation shall be engineered to withstand [90] mph

windload. (Where applicable, wind load rating to be based on IBC 2003 or local code if more stringent.)

1.5 SUBMITTALS

A. Product Data: For each product indicated, include manufacturer’s product literature, shop drawings, and product performance data indicating compliance with this specification.

B. Installation Drawings: Show layout, locations, components, materials, dimensions, sizes, weights, finishes of components, installation and operational clearances, gate

swings, post sizes, spacing and mesh type, gate details/dimensions, details of post anchorage, and post attachment/bracing.

C. Samples: Submit color selections and samples for finishes on fence and accessories if requested by the specifier.

1.6 QUALITY ASSURANCE

A. The contractor shall provide laborers and supervisors who are thoroughly familiar with the type of construction involved and the materials and techniques specified. Review

and follow manufacturer’s installation instructions.

B. Provide fence system and gates, as a complete unit produced by a single manufacturer, including necessary erection accessories, fittings and fastenings.

C. Manufacturer Qualifications: Company specializing in manufacturing the products specified in this section with a minimum of 10 years documented experience.

D. Field Quality Control to be conducted by (Owner’s Project Manager)(General Contractor)(Manufacturers Technical Specialist).

1.7 DELIVERY, HANDLING AND STORAGE

A. Deliver fence materials, gates, posts, and accessories to project site, completely pre-finished. Upon receipt at the job site, all materials shall be checked to ensure that no

damages occurred during shipping. Materials shall be handled and stored properly to protect against damage and theft.

B. Handle fence components to protect finish coating from any scuffs, abrasion or other damage during unloading and installation. Excessive damage to factory applied coatings

will be cause for rejection.

PART 2 – PRODUCTS

2.1 MANUFACTURER

A. MFR Manufacturing Corp, Inc. Aurora, IL 60506, Tel: 815-318-0839, Fax: 815-552-3315

E-mail: [email protected] Web: www.mfrcorp.com

2.2 MATERIAL

A. Fencing System: Subject to the performance and design requirement specified herein, fence and gates shall be manufactured from the following materials:

1. Wire Mesh Panels: Panels shall be 8′-3″ (2500mm) wide x [4’, 5’, 6’ or 8’] (1230mm/1530mm/1730mm/2430mm) high.

a. Panels shall be welded by resistance as per ASTM A185 using 6.5 gauge (.185”) Galfan coated steel wire.

b. The wire shall have a tensile strength of at least 75,000 lbs / in2, and 2127 lbs break strength.

c. Applied on wire, 150 g/m2 (.5 oz. / sq ft.) zinc-aluminum coating conforming to ASTM A641, class 1.

d. Horizontal and Vertical wires shall be welded to form 2” x 7.87“(50mm x 200mm) rectangles.

e. Panels shall have a number of folds according to the table below depending on the respective height of the panel.

| Panel Height | 4’ | 5’ | 6’ | 7′ | 8’ |

| 1230mm | 1530mm | 1730mm | 2130mm | 2430mm | |

| Reinforcement Ribs | 2 | 3 | 3 | 4 | 4 |

f. Exterior surface shall have a 2 to 4 mil polyester coating applied after fabrication as described in section 2.3.

g. The vertical wires of the mesh shall extend 1” from the last or first horizontal wire thereby creating a spiked top or bottom, depending on its position when installed

2. Square or Rectangular Tubular Posts:

a. Steel Posts to be per ASTM F2408 with increased strength to a minimum yield strength of 50,000 psi.

b. Material greater than 8 ga and larger than 4 inch O.D. shall be formed per ASTM A53, ASTM A500 Grade B, or ASTM A501, with a minimum yield of 46,000 psi and shall

be hot dipped galvanized in accordance with ASTM A123.

3. Fittings and Fasteners:

a. Post caps shall be of press on type steel caps zinc plated to ASTM B633, Service class II or malleable steel caps galvanized to ASTM A123, finished to match fence

finish and color or black UV resistant press insert caps.

b. Post brackets shall be galvanized steel with stainless, galvanized or zinc plated fasteners. All brackets shall be finished to match fence finish and color.

4. Swing Gates: Design of gates shall be as shown on the Drawings.

a. Gate Frames and Infill Panels: Materials as described above.

b. Frame Members: Shall be MIG welded. If necessary, truss rods or cables to be used to prevent gate sag and allow for future adjustment.

c. Gate Posts and Foundation: Size as determined by Engineer, based on gate size, local wind loading requirements, and installation type.

d. Hinges: Manufacturer’s standard hinges, structurally capable of supporting gate leaf and allow opening and closing without binding. Non-lift-off type hinge design shall

permit gate to swing 180⁰ (degrees). Hinge pins shall be non-removable.

e. Latch: Capable of retaining gate in closed position and have provision for padlock.

f. Keeper: Provide keeper for each gate leaf over 5 feet wide. Gate keeper shall consist of mechanical device for securing free end of gate when in full open position.

5. Slide, Cantilever and Overhead Track Gates Design of gates shall be as shown on the Drawings.

a. Gate Frames and Infill Panels: Materials as described above in 2.2.1.1.

b. Frame members: Shall be MIG welded. If necessary, truss rods or cables to be used to prevent gate sag and allow for future adjustment.

c. Gate Posts: Size as determined by Engineer, based on gate size, local wind loading requirements, and installation type.

2.3. POWDER COATED FACTORY FINISH

A. Coating Material: Posts, post caps, brackets, and wire mesh panels shall be finished with a factory-applied TGIC polyester powder coating of the “Super-Durable” class. Powder

coated finish shall meet or exceed the following performance criteria.

B. Applicable Requirements to Validate the Coating Process:

1. Adhesion Resistance: ASTM D3359, Measuring Adhesion by Tape Test, Method B.

a. Minimum Performance Requirement: Coating retention of not less than 95%.

2. Impact Resistance: ASTM D2794, Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact).

a. Minimum Performance Requirement: resistance to impact not less than 120 in. /lb.

3. Film Hardness ASTM D3363, Film Hardness by Pencil Test

a. Minimum Performance Requirement – Minimum Hardness: 2H.

4. Solar Concentration Exposure: ASTM D4141, Conducting Black Box and Solar Concentrating Exposures of Coatings, Method C. (Equivalent to EMMAQUA NTW)

a. Minimum Performance Requirement – coating must test to a minimum of 50% Gloss Retention at 1,400 MJ/m2 with no film failure, chalking, cracking or checking and no

more than 10% fading.

5. Thickness: Provide film thickness of 2-4 mils as measured by manufacturer’s standard powder coat measurement and inspection procedures.

6. Pretreatment: The fence sheeting and framework shall be prepared using a pre-treatment cleaning system to remove foreign material and to properly prepare the surface to

achieve the coating system requirements specified above.

7. Curing: Heat cure in accordance with powder manufacturer’s prescribed cure schedule to properly crosslink and bond finish to metal substrate.

8. Chemical Resistance:

a. Muriatic Acid Resistance (15 minute spot test)

1) Procedure: Apply 10 drops of 10% (by volume) solution of muriatic acid (37% commercial grade hydrochloric acid) in tap water on the coated surface and cover it

with a watch glass, convex side up. The acid solution and test shall be conducted a 18° to 27°C (65° to 80°F). After a 15 minute exposure, wash off with running

tap water.

a) Performance: No blistering and no visual change in appearance when examined by the unaided eye.

b. Mortar Resistance (24 hour pat test)

1) Procedure: Prepare mortar by mixing 75g (2.6 oz) of building lime (conforming to ASTM C207) and 225g (7.9 oz) of dry sand, both passing through a 10-mesh wire

screen with sufficient water, approximately 100g (3.5 oz), to make a soft paste. Immediately apply wet pats mortar about 1300 mm² (2 in²) in area and 12 mm (1/2

in) in thickness to coated specimens, which have been aged at least 24 hours after coating. Immediately expose test specimens for 24 hours to 100% relative

humidity at 38°C (100°F).

a) Performance: Mortar shall dislodge easily from the coated surface, and any residue shall be removable with a damp cloth. Any lime residue should be easily

removed with the 10% muriatic acid solution. There shall be no loss of film adhesion or visual change in the appearance when examined by the unaided eye.

Note: A slight staining or discoloration may be apparent on orange, yellow or metallic coatings. This should be discussed with the specifying source prior to

selection of color.

c. Detergent Resistance

1) Procedure: Prepare a 3% (by weight) solution of detergent as prescribed in ASTM D2248, and distilled water. Immerse at least two test specimens in the

detergent solution at 38°C (100°) for 72 hours. Remove and wipe the specimens dry. Immediately apply tape (Permacel 99 or equivalent) 20 mm (3/4 in) wide by

pressing down firmly against the coating to eliminate voids and air pockets. Place the tape longitudinally along the entire length of the test specimens. If blisters

are visible, then the blistered area must be taped and rated. Sharply pull off at a right angle to the plane of the surface being tested, per ASTM D3359.

a) Performance: No loss of adhesion of the film to the metal. No blistering and no significant visual change in the appearance when examined by the unaided

eye.

d. Corrosion Resistance:

1) Procedure: Preparation of Test Specimens- Perform a single scribe the length of the specimen, within one inches of any edge and deep enough to expose the

base metal. Expose the specimen for 1,000 hours according to ASTM B117-07 using a 5% salt solution and 95°F operational temperature. After exposure, remove

specimens and wipe dry. Immediately apply tape (Permacel 99 or equal) over scribed are by pressing down firmly against the coating. Sharply pull the tape off at a

right angle to the surface being tested.

a) Performance: The required is a minimum of seven on the scribed edge and minimum blister rating of eight within the test specimen field in accordance with

tables in ASTM D1654.

2.4 CONCRETE FOOTINGS

*This section shall be superseded by requirements of anti-ram barrier system if used in conjunction with this installation*

A. General: Comply with ACI 301 for cast-in-place concrete; materials consisting of Portland cement complying with ASTM C150, aggregates complying with ASTM C33, and potable

water.

B. Concrete Mixes: Normal-weight concrete air entrained with not less than 3000-psi (20.7- MPa) compressive strength (28 days), 3-inch (75-mm) slump, and 1-inch (25-mm)

maximum size aggregate.

C. Footings: Footings shall be minimum 3,000 psi after twenty-eight (28) days concrete. Footing sizes shall be determined by Engineer.

PART 3 – EXECUTION

3.1 PREPARATION

A. Verify areas to receive fencing.

B. Coordinate fence installation with work of other sections listed in these specifications.

C. Examine conditions under which fencing and gates are to be installed. Notify Contractor of unsatisfactory conditions. Do not proceed with work until conditions are satisfactory

to the installer.

3.2 INSTALLATION

A. Install fence and gates in accordance with manufacturer’s instructions and approved installation drawings. Install fencing to withstand wind load as specified.

B. Handle fence components to protect finish coating from any scuffs, abrasion or other damage during installation. Excessive damage to factory applied coatings will be cause for

rejection.

C. Space posts at dimensions indicated in the installation drawings. Attach fence rails to posts using stainless steel or galvanized steel, panel hanger brackets supplied by

manufacturer. Field welding of panels to posts is unacceptable as it will cause significant damage to the galvanizing and powder coat protective finishes.

D. Concrete Footings: Place concrete around posts and vibrate or tamp for consolidation. Verify that posts are set plumb, aligned, and at correct height and spacing, and stabilized

in position during placement and finishing operations until concrete is sufficiently cured. Protect portion of posts above ground from concrete splatter.

E. Install gates level, plumb, and secure for full opening without interference. Attach hardware using tamper-resistant or concealed means. Install ground-set items in concrete for

anchorage. Adjust gate to operate smoothly, easily, and quietly throughout entire operational range. Confirm that latches and locks engage accurately and securely without

forcing or binding.

F. Avoid unnecessary cutting, drilling and welding of pre-finished fence components. If necessary to cut drill, weld or otherwise modify product due to field conditions, repair

factory finish in accordance with item below.

G. Touch-up any necessary areas by lightly sanding; clean area thoroughly, apply a zinc-rich cold galvanizing primer followed by a high quality acrylic lacquer paint to match finish.

(Touch-up paint available from manufacturer) Note: field applied touch-up cannot match the performance of factory applied finishes and should be limited in use.

3.3 CLEANING

A. Fence contractor shall remove packing materials and unused product and level uneven areas due to excavations created by fence installations.

END OF SECTION 32 31 16

Finish. Colors. Coating.

The railing systems high rigidity is accomplished by use of combined steel bars which electro forged cross rods. Wide selection of a variety of different mesh sizes to match your project needs. All railing systems are designed to meet the strength requirements of standard building codes. Custom engineered systems can be designed to match any strength requirement for specific local building codes.(i.e. high rise roof top railings)

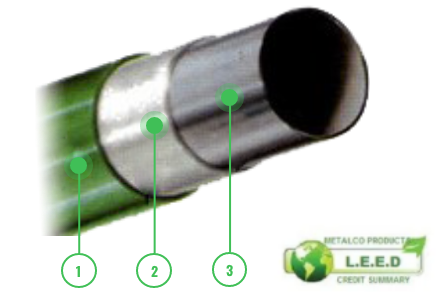

- Polyester Coating 90/100 micron

- Zinc base E-Coat layer and zinc rich powder layer / alternate hot dip galvanized zinc coating ASTM123

- High Strength Steel

*may vary by product type

Powder Coating is Eco Friendly

Our Powder Coatings are environmentally friendly and are an organic high quality finished surface providing integrity, durability, and a beautiful appearance over an extended period of time.

Powder Coating has been proven to be safer for the environment than wet paint applications. Most wet paints have solvents that are harmful to the environment. However, powder coat is solvent-free and applied electrostatically.

Ecologically there are no VOCs emitted and very little waste is produced because most powder coating overspray can be reused, greatly reducing the waste commonly found in liquid painting.

Environmental Impact of Powder Coating

Despite all the care that is taken to protect the environment, there are still benefits to be gained.

More importantly, the long term effect of powder coating the product for corrosion protection. Our coating system protects the metals which are exposed to the project conditions, which in turn enjoy a longer lifetime and require far less maintenance. Decay and early replacement of parts are prevented or at best minimized.

In the long run, powder coating will replace its counterpart, wet paint, in more and more areas. Technically, powder coating competes with wet paint head to head. In addition, powder coating is more friendly to the environment than wet paint, for the same cost, yet powder coating also has the advantage of superior mechanical and anti-corrosive properties. Whereas wet paint is all washed up!

Another advantage of using powder coatings is the subtraction of solvents. The powder is applied without any additives. The harmful emission of V.O.C., as used in wet paint, does not occur. The environment also benefits from the electrostatic adhesion of the metal to the powder particles. This adhesion creates a smooth and even layer that covers the edges of the metal object. This eliminates sharp edges that need to be ground into shape. The powder, not attracted to the substrate is contained and reused. Wet paint overspray has to be disposed of as chemical waste.

To protect steel from being affected by corrosion it may be provided with a powder coating. During this process, powder is electrostatically applied to galvanized or a black steel product. It is then cured. The very durable coating that is formed protects the underlying metal and gives the object a shiny and bright appearance.

Powder coatings are applied to steel, hot dip galvanized steel and aluminum as an anti-corrosive layer. The powder is electrostatically applied to the metal. No solvents are used in this process, which means that it is far more friendly to the environment than the alternative wet paint process. Powder that is not adhered can be reused, whereas over sprayed wet paint has to be disposed of as chemical waste.

Powder coatings have outstanding mechanical properties, they are elastic and resistant to impact and wear. This makes powder coating ideal for applications in areas with a high risk of damage, such as stairwells, public areas, gates, lamp posts, etc.

The method for applying powder coating, electrostatic spraying, results in a very good coverage of edges. This sharply contrasts with the wet paint process, where the pressure of the spray gun pushes the paint off the sharp edges. During the powder coating, the powder is attracted evenly to all surfaces.

Hot-dip galvanization is the process of coating iron and steel with a layer of zinc by immersing the metal in a batch of molten zinc at a temperature of around 840 F (449 C). The process is inherently simple which provides a distinct advantage over other corrosion protection methods. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly-bonded alloy coating that provides superior corrosion protection to steel.

In one word; protection. The best possible protection for steel and iron against corrosion. For more than 150 years, hot-dip galvanizing after fabrication has been specified to combat steel corrosion in the harshest environments throughout various markets. Hot-dip galvanizing (HDG) is often used to protect steel from corrosion in some of the harshest environments imaginable, yet it provides maintenance-free longevity for decades.

One reason are size limitations. The other is the finish itself. The zinc has a tendency to build up differently on welds. Also differently on some parts where the chemical composition is even slightly different. This causes uneven surfaces with drips, drops, bumps and other impurities. These are inherent in the hot dip galvanizing process and cannot be avoided or completely controlled. Please expect a certain amount of roughness on fabricated and welded steel to appear after the hot dip galvanizing. Sanding or filing down is NOT recommended as not to disturb the protection against rust and corrosion or void the warranty.

Do NOT specify hot dip galvanizing if you expect a perfect or “car like” paint finish. Despite that disadvantage we recommend hot dip galvanizing for out door application in rough climates or where salt spray during the winter months is expected. We do not feel hot dip galvanizing is needed for interior application of in climates where a regular powder coated or paint finish is providing sufficient protection against corrosion.

Do NOT specify hot dip galvanizing in coastal areas or tropical climates. We define coastal areas within 20 miles from large bodies of sea (salt) water. It is correct that hot dip galvanized performs very well in winter climates and protects steel well against street salt, however it does not perform well as a final coat or finish in areas with ocean spray or ocean salt spray in the air. Do NOT specify hot dip galvanized in coastal or certain tropical areas if you intent to utilize a polyester powder top coat. The adhesion of conventional polyester powder coatings tend to break down in these climates if applied onto hot dip galvanized surfaces. Please ask for our special PLASCOAT finishes for applications in such problem areas.

Brochures

Have our brochures mailed to you!

Download a PDF version of our brochure now.

PRODUCT Showcase

Organizations that use our products