Metalco “Grigliato” SC Louver Screen

Metalco Façade Screen Systems

If you have a challenging project that needs “special attention” turn to Metalco for custom solutions created by a top-shelf team of engineers and architects.

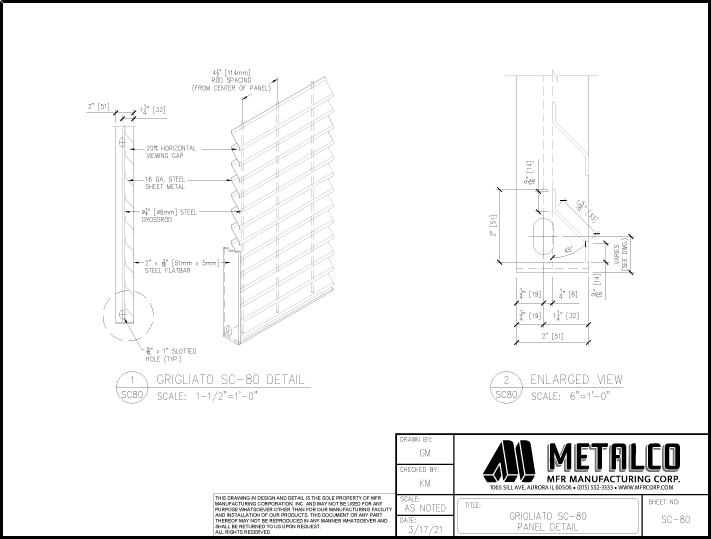

The “Grigliato” Architectural Screen System – Over the past two decades, Metalco’s “Grigliato” Architectural Screen System has proven its ability to accommodate even the most demanding design needs. Successfully incorporated into a variety of projects such as parking garages, equipment enclosures, building façade screens, planting screens, educational facilities and others. Both our “SC” Louver screen products and our “Select” products are commonly used for a variety of architectural partition solutions.

The “Grigliato SC” Louver product is ideal for a fence or façade screen where some visual privacy is needed without obstructing airflow. Visual screening is variable at 100% horizontal screening, 80% horizontal screening, and 60% horizontal screening.

Environmentally Responsible

Twenty Year Warranty

American Made

25 Years of Experience

- Key Benefits

- CAD Drawings

- Specifications

- Finish & Colors

- Brochures

Key Benefits

- Overview

- RIGIDITY

- MODULAR SYSTEM

- LONGEVITY

- EASE OF INSTALLATION

- PANELS

- POSTS

- COATING

- COLORS

- WARRANTY

The METALCO Screen and Curtain Wall Facade Systems are based on the “Grigliato” Architectural Grille panels and can also incorporate the “Grigliato” “SC” louver panels. The large selection of different panel types and mesh sizes enables the designer to meet many design and functionality requirements. Special Design Effects can be achieved by combining different panel types into patterns.

Design requirements such as airflow restriction, wind load resistance, visual screening and structural support had been thoroughly addressed. Please consult with our engineering team to learn how we can provide practical solutions for your project.

RIGIDITY

The screen system’s high rigidity is accomplished by use of combined steel bars which electro forged cross rods. Wide selection of a variety of different mesh sizes to match your project needs. All railing systems are designed to meet the strength requirements of standard building codes. Custom engineered systems can be designed to match any strength requirement for specific local building codes.(i.e. wind load requirements, air flow restrictions ect.)

MODULAR SYSTEM

The screen system is provided as a complete modular system consisting of components in various sizes, support structure elements, rails and attachment hardware.

LONGEVITY

METALCO’s advanced polyester powder coating system assures lasting colors. The combined protection of galvanization and powder coating ensures best protection against rust and corrosion.

EASE OF INSTALLATION

The “GRIGLIATO” system components are developed with ease of installation in mind. All items are pre-manufactured to allow for a bolted installation with no or very little on-site cutting or welding required.

PANELS

“GRIGLIATO” architectural facade screen systems are custom manufactured to match your project requirements. The system is based on “GRIGLIATO” infill panels which are available in a variety of different styles, mesh sizes and finishes. The panels are made from a combination of steel bars and rods which are electroforged welded on a fully automated production line. The panel sizes, frame post spacing, frame types and other details are custom engineered for your specific application. Large mesh sizes can be used for unobtrusive sight lines. Smaller mesh sizes are often used to accomplish a certain visual appeal or design effect.

POSTS

The “GRIGLIATO” architectural screen system is available with a variety of different support structures and frames. Mostly used are 2″x2″ or larger square tubular supports, 1-1/2″ x 2-1/2″ rectangular supports or flat bar braces. In addition a variety of custom attachments, subframe designs and support posts are available.

COATING

Depending on requirements mesh panels may be hot dip galvanized after fabrication and coated with an architectural grade polyester powder coating system. Our coating system offers the highest durability available today resulting in lasting colors for many years. In addition to the best protection against rust and corrosion it is also environmentally friendlier (no solvents) than other technologies.

COLORS

The “GRIGLIATO” screen system is available in a variety of standard colors. Custom colors are available and special colors can be matched to color samples or other or existing building components. Click here for more color info.

WARRANTY

The “GRIGLIATO” Screen System is produced by utilizing state of the art manufacturing technology and is backed by our 20-year Manufacturer’s Warranty.

Specifications

Specifications

MFR Manufacturing Corp offers technical assistance to architects, engineers, contractors, owners and facility managers regarding the design and installation of our products. We have provided many custom solutions for unusual situations. Let our experienced engineers assist you in determing the optimum design for your project.

MR-MANUFACTURER

MFR Manufacturing Corp, Inc.,

1065 Sill Ave

Aurora, IL 60506

Tel: 815-318-0839 FAX: 815-552-3315

e-mail: [email protected]

PP-PRODUCT PRESENTATION

The “Grigliato” screen system utilizes the strength and flexibility of the “Grigliato” panels from MFR .

The “Grigliato” System enables us to offer an affordable modular system, which is practical, durable and sturdy. This unique railing system provides a wide variety of design solutions. It can be brightly colored and configured to be a design feature or it can blend inconspicuously with the surroundings.

The “Grigliato” panels are ideally suited for retrofitting existing railing systems, which are not in compliance with current building codes.

“Grigliato” is an electro-forged welded steel panel. The panels are hot-dip galvanized according to ASTM A 123. Also available as an option is our extremely durable polyester powder finish.

Screen System

The MFR screen system can span between post supports or be mounted onto structurally suitable elements. Please contact MFR Manufacturing Corp for engineering and design assistance when preparing detail solutions.

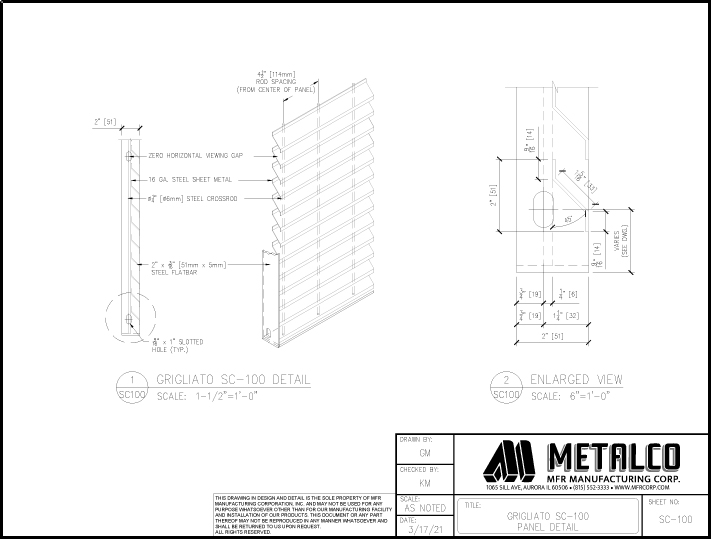

“Grigliato SC” Panel Types

GRIGLIATO SC100 , louver mesh 4-1/2” x 1 15/16””, steel profile on wire rod dia. 1/4” (minimal airflow restriction, 100% visual screening)

GRIGLIATO SC80 , louver mesh 4-1/2” x 2-1/2” , steel profile on wire rod dia. 1/4” (minimal airflow restriction, 80% visual screening)

Curved Panels

All “Grigliato” panels are available in a curved design. The minimum radius that can be rolled is 9″. The radius would be perpendicular to the steel bar.

AI-ASSEMBLY, INSTALLATION

Posts can be attached to the structure below in several ways: Using the recessed method, posts are set into cored holes or sleeves and anchored with non-shrink grout.

Using the surface mount method, mounting plates attached to each post are expansion bolted to the structure below.

In the face mount method, the railing posts are mounted to the face of the structure typically below the level of the walking surface.

MF-MATERIALS, FINISHES

Thermosetting Polyester Powder Finish

MFR Fence and railing panels are protected by what we believe is the best finish available today. The computer controlled hot-dip galvanizing and the thermosetting polyester powder finish give the MFR System the highest possible protection against rust and corrosion.

The advanced polyester powder coating technology is environmentally friendly (no solvents, lead free) and offers a large color selection.

Colors

Eight standard colors are available: white, black, blue, green, red, yellow, gray and brown. Additionally, we offer an almost unlimited selection of custom colors. The polyester powder coating is available for all our products including oversized parts, i.e. large gates.

20-Year Limited Warranty

MFR fencing systems are free from defects in material and workmanship.

The hot-dip galvanized coating can leave minor impurities on the treated surface, i.e., flashing, drips, drops, etc. These do not impair the coating in terms of corrosion resistance. The polyester coated galvanized metal is guaranteed not to rust, crack, peel or blister for a period of 10 years. Accidental damages, defects resulting from improper installation and damage from vandalism or abuse are not included. Warranty is limited to a prorated value of the coating, not to exceed the original value of the coating.

For a detailed warranty certificate click on the PDF button.

TD-TECHNICAL DATA

Applicable Standards:

Material: Bar Stock: ASTM A 36, Tube: ASTM A 500-Grade B

Fabrication: ANSI/AWS D1.1

Hot-Dip Galvanized: ASTM A 123

Cadmium Plating: ANSI/ASTM A 165-71, Type NS with a clear chromate finish

Powder Coating: Hardness ASTM D 3363; Direct impact ASTM D 2793. Salt spray resistance test ASTM B 117, Weatherability ASTM D822 In the interest of improving quality and design, Atlantis Products, Inc., Inc. reserves the right to change specifications without prior notice.

CC-CODES, CERTIFICATIONS

The installed system can be designed to be capable of withstanding 1) a concentrated load of 200 lbs. applied at any point in any direction 2) a uniform load of 50 lbs. per linear ft. applied horizontally and concurrently with uniform load of 100 lbs. Per linear ft. applied vertically downward. The infill area of the guardrail system is capable of withstanding a horizontal concentrated load of 200 lbs. applied to 1 sq. ft. at any point in the system.

AC-AVAILABILITY, COST

Availability: MFR fencing is carried in stock in large mats or prefabricated panels. Jobs are fabricated and coated before being shipped throughout the United States. Cost: Costs are quoted on a per-job basis due to varying requirements of each project. Costs may be obtained by calling:

MFR Manufacturing Corp, Inc.

TEL 815-318-0839

FAX 815-552-3315

WEB SITE: www.mfrcorp.com

E-MAIL: [email protected]

OM-OPERATION, MAINTENANCE

The advanced coating method supplied on the Metalco screen systems requires no maintenance.

Finish. Colors. Coating.

The railing systems high rigidity is accomplished by use of combined steel bars which electro forged cross rods. Wide selection of a variety of different mesh sizes to match your project needs. All railing systems are designed to meet the strength requirements of standard building codes. Custom engineered systems can be designed to match any strength requirement for specific local building codes.(i.e. high rise roof top railings)

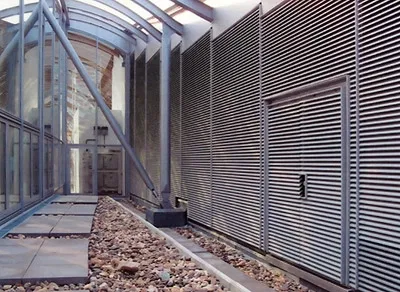

- Polyester Coating 90/100 micron

- Zinc base E-Coat layer and zinc rich powder layer / alternate hot dip galvanized zinc coating ASTM123

- High Strength Steel

*may vary by product type

Powder Coating is Eco Friendly

Our Powder Coatings are environmentally friendly and are an organic high quality finished surface providing integrity, durability, and a beautiful appearance over an extended period of time.

Powder Coating has been proven to be safer for the environment than wet paint applications. Most wet paints have solvents that are harmful to the environment. However, powder coat is solvent-free and applied electrostatically.

Ecologically there are no VOCs emitted and very little waste is produced because most powder coating overspray can be reused, greatly reducing the waste commonly found in liquid painting.

Environmental Impact of Powder Coating

Despite all the care that is taken to protect the environment, there are still benefits to be gained.

More importantly, the long term effect of powder coating the product for corrosion protection. Our coating system protects the metals which are exposed to the project conditions, which in turn enjoy a longer lifetime and require far less maintenance. Decay and early replacement of parts are prevented or at best minimized.

In the long run, powder coating will replace its counterpart, wet paint, in more and more areas. Technically, powder coating competes with wet paint head to head. In addition, powder coating is more friendly to the environment than wet paint, for the same cost, yet powder coating also has the advantage of superior mechanical and anti-corrosive properties. Whereas wet paint is all washed up!

Another advantage of using powder coatings is the subtraction of solvents. The powder is applied without any additives. The harmful emission of V.O.C., as used in wet paint, does not occur. The environment also benefits from the electrostatic adhesion of the metal to the powder particles. This adhesion creates a smooth and even layer that covers the edges of the metal object. This eliminates sharp edges that need to be ground into shape. The powder, not attracted to the substrate is contained and reused. Wet paint overspray has to be disposed of as chemical waste.

To protect steel from being affected by corrosion it may be provided with a powder coating. During this process, powder is electrostatically applied to galvanized or a black steel product. It is then cured. The very durable coating that is formed protects the underlying metal and gives the object a shiny and bright appearance.

Powder coatings are applied to steel, hot dip galvanized steel and aluminum as an anti-corrosive layer. The powder is electrostatically applied to the metal. No solvents are used in this process, which means that it is far more friendly to the environment than the alternative wet paint process. Powder that is not adhered can be reused, whereas over sprayed wet paint has to be disposed of as chemical waste.

Powder coatings have outstanding mechanical properties, they are elastic and resistant to impact and wear. This makes powder coating ideal for applications in areas with a high risk of damage, such as stairwells, public areas, gates, lamp posts, etc.

The method for applying powder coating, electrostatic spraying, results in a very good coverage of edges. This sharply contrasts with the wet paint process, where the pressure of the spray gun pushes the paint off the sharp edges. During the powder coating, the powder is attracted evenly to all surfaces.

Hot-dip galvanization is the process of coating iron and steel with a layer of zinc by immersing the metal in a batch of molten zinc at a temperature of around 840 F (449 C). The process is inherently simple which provides a distinct advantage over other corrosion protection methods. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly-bonded alloy coating that provides superior corrosion protection to steel.

In one word; protection. The best possible protection for steel and iron against corrosion. For more than 150 years, hot-dip galvanizing after fabrication has been specified to combat steel corrosion in the harshest environments throughout various markets. Hot-dip galvanizing (HDG) is often used to protect steel from corrosion in some of the harshest environments imaginable, yet it provides maintenance-free longevity for decades.

One reason are size limitations. The other is the finish itself. The zinc has a tendency to build up differently on welds. Also differently on some parts where the chemical composition is even slightly different. This causes uneven surfaces with drips, drops, bumps and other impurities. These are inherent in the hot dip galvanizing process and cannot be avoided or completely controlled. Please expect a certain amount of roughness on fabricated and welded steel to appear after the hot dip galvanizing. Sanding or filing down is NOT recommended as not to disturb the protection against rust and corrosion or void the warranty.

Do NOT specify hot dip galvanizing if you expect a perfect or “car like” paint finish. Despite that disadvantage we recommend hot dip galvanizing for out door application in rough climates or where salt spray during the winter months is expected. We do not feel hot dip galvanizing is needed for interior application of in climates where a regular powder coated or paint finish is providing sufficient protection against corrosion.

Do NOT specify hot dip galvanizing in coastal areas or tropical climates. We define coastal areas within 20 miles from large bodies of sea (salt) water. It is correct that hot dip galvanized performs very well in winter climates and protects steel well against street salt, however it does not perform well as a final coat or finish in areas with ocean spray or ocean salt spray in the air. Do NOT specify hot dip galvanized in coastal or certain tropical areas if you intent to utilize a polyester powder top coat. The adhesion of conventional polyester powder coatings tend to break down in these climates if applied onto hot dip galvanized surfaces. Please ask for our special PLASCOAT finishes for applications in such problem areas.

Brochures

Have our brochures mailed to you!

Download a PDF version of our brochure now.

PRODUCT Showcase

Organizations that use our products